Features

- Magnetic power above 100 MT/m2.

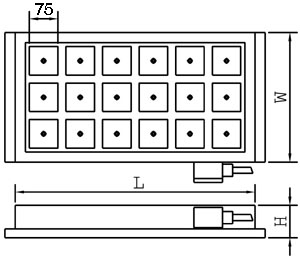

- Magnetic Pole Size: 75 x 75 mm.

- Perfect safety in case of power failure. No electricity needed to Keep the Electro Permanent Magnetic Chuck ON.

- Unobstructed movement of cutters during machining.

- Variable magnetic power.

- Drastically reduces set up Time by using magnets.

- Achieves best machining accuracy.

- Uniform clamping over entire area, such no chattering of tools there by improving finish and tool life.

- Reduce Clamping/ De-clamping time in CNC machines drastically resulting in increased production.

|

Applications

- Electro Permanent Magnetic (EPM) Chuck are most suitable for heavy duty milling operations on medium, large size and even rough components.

- A minimum of 4 alternate magnetic poles contact is necessary for optimum clamping.

- Minimum thickness of job being clamped magnetically should be 20 mm.

- All five faces of the job can be machined in the same setting if clamped magnetically.

- EPM Chuck is easily integrated with Pallet changing and FMS Systems.

- AUTOMATIC SHIMMING: Spring Loaded pole extensions allow to clamp and to support uniformly work pieces even with bent surfaces achieving high accuracies of planarity.

- The Magnet can be designed for 220/380/400/480 VAC, 50/60 Hz.

- Custom designed solutions also available.

|

|